The 9-Second Trick For 24??media

The 9-Second Trick For 24??media

Blog Article

Facts About 24??media Revealed

Table of ContentsExamine This Report on 24??mediaThe 3-Minute Rule for 24??mediaWhat Does 24??media Mean?Rumored Buzz on 24??mediaOur 24??media Statements

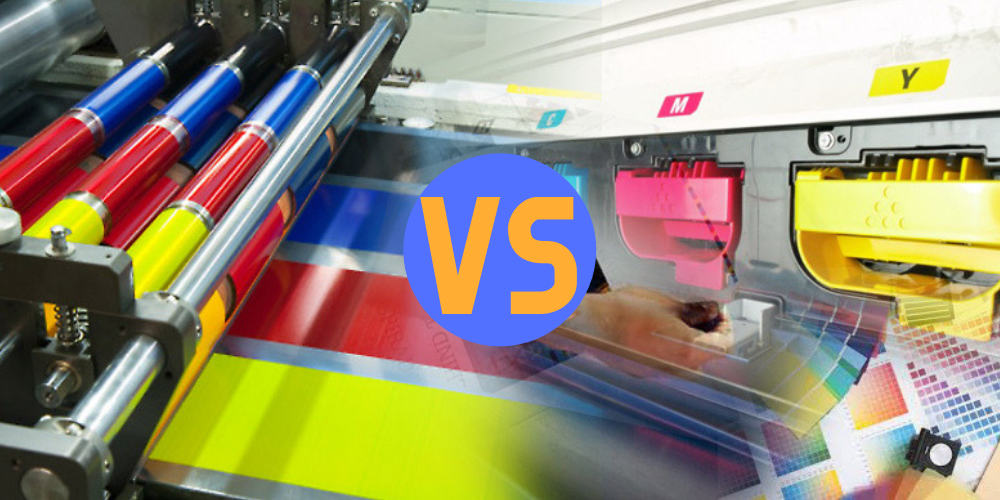

Improvements in print innovation are transforming the interactions playing field when it involves top quality, cost and innovative capabilities. Offset printing and digital printing are the major processes whereby print work are carried out both using four-color printing methods. Each alternative has its advantages, using various techniques to meet the requirements of diverse manufacturing projects.

Typically, this has been the most constant technique for specifically keeping color suits, making it ideal for print runs that only need static printing such as pre-printed forms, brochures, flyers, company cards, and bulk postcard mailings. Due to the static nature of litho printing, it is not optimal for variable print pieces that will be sent by mail to specific recipients such as statements, letters, and personalized postcards.

Top Guidelines Of 24??media

The current innovations in print modern technology are aiding to bring most of balanced out's advantages into the electronic printing world truly transforming the face of contemporary printing! There are some vital differences between Offset Printing and Digital Printing (Wallpaper). This guide reveals the advantages and drawbacks of each printing method. There is an undeniable and expanding number of benefits to making use of the electronic print procedure.

Today's electronic print equipment is among the most innovative on the marketplace. Here are a few of the most significant benefits of making use of digital printing: dominate the electronic print area, with full-color printing finished in one process and seamlessly printed straight from a print data. Without a lengthy set-up procedure, the calibration time of a certain task is reduced, contributing to quicker print time and general delivery.

The inkjet printing process has assisted to reinvent the market as well as the high quality and rate of the result. The latest inkjet technology can publish on standard offset supplies with dull, silk, and glossy finishes. High-grade electronic print coupled with software-managed color administration techniques adds maximum value to print pieces and makes manufacturing processes extra trustworthy than offset.

The Single Strategy To Use For 24??media

(https://za24media.carrd.co/)

Precise quantities of ink and printer toner are made use of to avoid waste. Environmentally friendly and biodegradable inks and printer toners are likewise readily available for more sustainable printing. Digital print also gets rid of the demand to wash plates or coverings with harmful chemicals at the end of the printing process. As the top quality of electronic print services enhances, the benefits become increasingly obvious and beneficial.

Variable information aids services reach their exact clients and target market with uniquely-created and customized web content. As modern technology boosts, the high quality of electronic printing has actually become second-to-none, with greater information, color suit capabilities and total accuracy. Without the demand to wash plates or utilize excess ink, digital printing is likewise much less wasteful and typically a lot more eco-friendly.

Typical printing approaches, such as countered lithography ("offset") and flexography ("flexo"), involve several make-ready actions to move an initial photo to a substratum. These methods call for the production of a collection of plates installed on a cyndrical tube to move ink that forms the desired image when integrated on paperboard and various other packaging products. Signage.

Getting The 24??media To Work

Digital printing, with fewer relocating items, is more nimble than offset in this regard.

Reduced set-up time conserves cash on the front end. And because these are not large bulk orders, smaller organizations can afford to publish without having more helpful hints to fulfill the greater and more expensive print thresholds of standard printing.

Make certain you team up with a printing and product packaging partner that has the best accreditations. While eleventh-hour printing and customization are a big advantage, electronic may not constantly be the best method for you. For instance, counter printing has the advantage of cost-effectiveness with huge print runs, especially those with sophisticated decorative impacts and specialty layers.

Indicators on 24??media You Need To Know

The favorable plate, with its smooth surface area, draws in oil-based inks and fends off water. In comparison, the unfavorable plate, with its rough texture, takes in water and wards off oil. Rubber rollers are then utilized to move the picture from the plate to the corrugated surface.

Corrugated paper can in some cases confirm to be a tough surface area to print on, but Litho prints to a separate surface area and is then laminated flooring to it, making it simple to print high-quality images. It can be incredibly consistent, also for long runs. The much more you print, the less costly the prices come to be for Litho.

What Litho doesn't provide you is exactly what Digital does, personalization. Pricey set up Longer turnaround No Variable Data Printing Smaller shade range, shades can be much less bright Digital printing is the procedure of printing electronic pictures directly onto the corrugated substratum making use of a single-pass, direct-to-corrugate technique.

Report this page